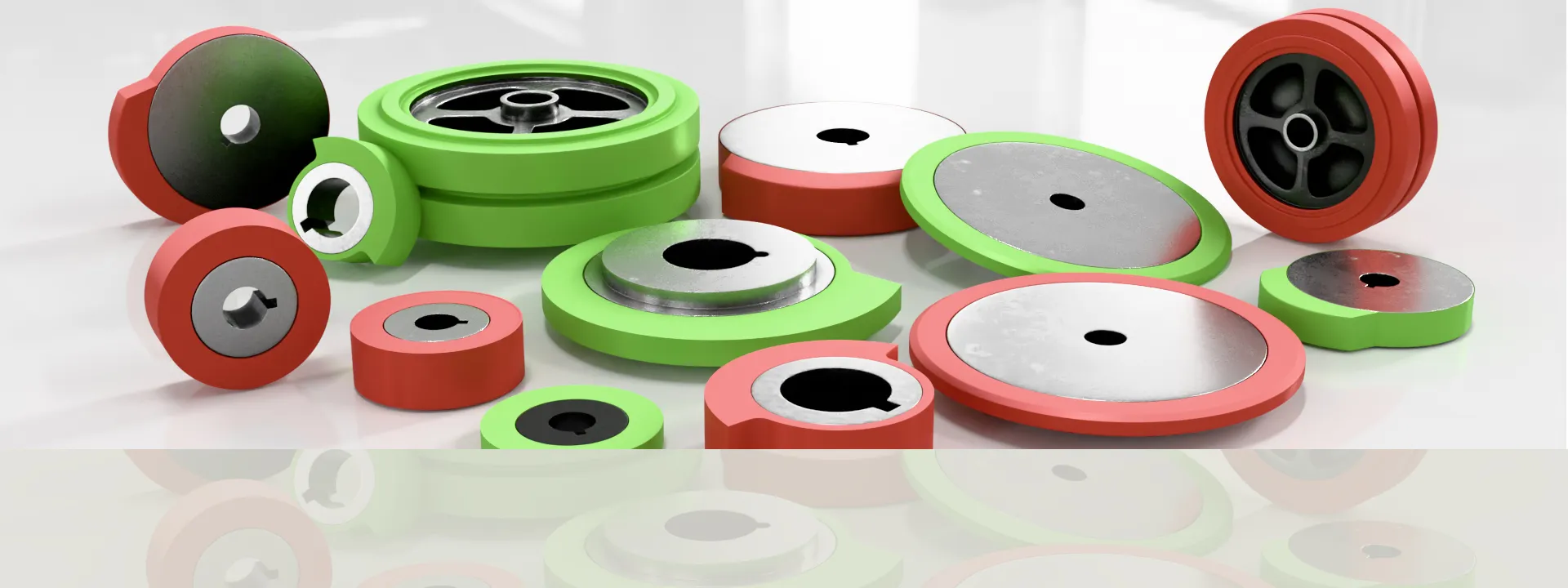

Large selection of Small, Big, Bright, Precise Printing Pads

Choosing the right tampon pad is essential for achieving successful and efficient pad printing operations. Here are some key factors to consider when selecting a tampon pad:

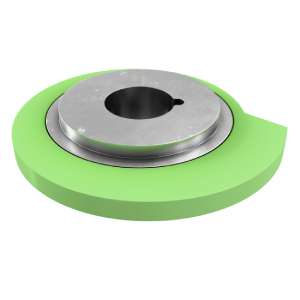

Tampon pads are typically made from silicone or rubber. The choice of material depends on factors such as the substrate material, ink compatibility, and the desired printing results. Silicone pads are known for their durability and excellent ink transfer, while rubber pads offer versatility and can be used in a variety of applications.

The hardness of the tampon pad significantly impacts ink transfer and image quality. Different printing requirements may necessitate pads with varying hardness levels. Softer pads are ideal for delicate or uneven surfaces, whereas harder pads are preferred for precise and detailed printing.

The shape and size of the tampon pad should correspond with the shape and size of the printing area. It is crucial to select a pad that fits the contours of the object being printed to ensure proper ink transfer and accurate image reproduction.

Tampon pads must be compatible with the ink used in the pad printing process. Consider factors such as ink viscosity, drying time, and adhesion properties to ensure optimal ink transfer and adhesion to the substrate.

The surface texture of the tampon pad can influence ink pickup and release. Depending on the printing requirements, you may choose pads with either smooth or textured surfaces to achieve the desired results.

Tampon pads should be durable enough to withstand repeated use without significant wear or deterioration. High-quality pads are designed to maintain their shape, hardness, and ink transfer properties over time, ensuring consistent print quality and reducing downtime.

Consider the ease of maintenance and cleaning when selecting tampon pads. Pads that are simple to clean and maintain enhance production efficiency and prolong the lifespan of the pads.

By carefully considering these factors, you can select the appropriate tampon pad that contributes to optimal ink transfer, precise image reproduction, and overall printing efficiency. Consulting with pad printing experts and suppliers can provide valuable guidance in choosing the right tampon pad for specific printing applications.

At Spinks World, we are proud to be a leading force in the industrial printing solutions industry, delivering customised products and comprehensive service packages designed to maximise your value. With over 30 years of experience, we’ve built a strong reputation as a trusted partner known for innovation, reliability, and technical excellence.

Our core mission is to help you optimise your processes by refining existing workflows and introducing new, more efficient methods tailored to your evolving production needs. We are committed to creating the right conditions for operational success, enabling you to get the most out of Spinks products while adapting seamlessly to changing market demands.

Our wide array of service offerings—including installation, maintenance, repairs, and system upgrades—is designed to enhance productivity and performance in a sustainable, cost-effective manner.

At Spinks World, we take pride in offering premium-quality silicone pads that are essential for delivering sharp, high-resolution prints in pad printing applications. Designed to transfer intricate images from the cliche to a variety of surfaces, our pads ensure consistency, precision, and durability with every print.

Our silicone pads are engineered to meet the evolving needs of modern printing processes. Whether you're printing on flat, curved, or irregular surfaces, Spinks silicone pads deliver optimal ink transfer and long-lasting performance, ensuring maximum uptime and minimal wear.